James Drummond & Son Mills, Lumb Lane Bradford.

The architects were Lockwood & Mawson who later designed City Hall, the mill was seen to be virtually finished in December 1885 but didn’t open for business till 1886 and after an eventfull history of 115 years finally closed in 2001.

*************************************************

Extract from the Illustrated Daily Telegraph, Saturday December 5th 1885.

The above is a sketch of one of the most extensive spinning and manufacturing concerns in Bradford.

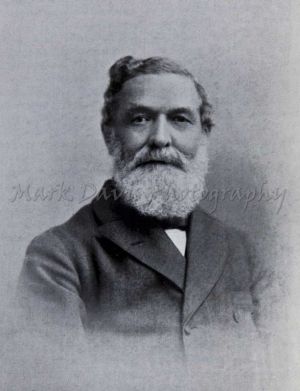

Its founder is Mr James Drummond, who may be regarded as another of the many self made men of Bradford, who, whilst making a position for themselves in the commercial world of the district, have at the same time materially helped to place Bradford in the high position she holds in the manufacturing communities of the world. The Lumb Lane Mills are the result of nearly half a century of arduous labour combined with much business acumen on the part of its founder, and are a monument to his perseverance and industry. It is now half a century since Mr James Drummond first became connected with the worsted trade of the town. In 1835 he became an apprentice to Messrs Lister, Spencer and Co. who at that period started the business of worsted spinners in Greenwoods Mill in Portland Street. The partners in the firm at that time were Mr Joshua Brooke Lister and Mr Thomas Spencer, who were the two managing partners. After a time the firm began manufacturing, and took a portion of Ducketts mill in Nelson Street, but this was subsequently relinquished. There was some time after a great fall in the price of wool, and business became very bad. During his apprenticeship, Mr Drummond had paid great attention to the classification of wool, and before he had completed his term of apprenticeship he went to Messrs Bottomleys at Shelf, to manage their wool department. The firm with which he first became connected changed to that of Thomas, Spencer and Co, and then to Spencer and Smith, and after this latter change Mr Drummond once more resumed work at Greenwood’s mill, Mr John Hill of Apperley, was a sleeping partner, the concern and Mr Spencer leaving, the title of the firm underwent a further change, being known as Hill and Smiths. During these successive transformations of the firm, Mr Drummond had been steadily improving his position, disclosing his business aptitude in a manner that commanded accordance and on a further change, taking place through the retirement of Mr Smith he became a partner, and the style of the firm was changed to Hill and Drummond. This was Mr. Drummond’s first step as one of the heads of a firm and will be seen that it has been fruitful of the best and most substantial results. After a while the new firm finding their business increasing took a portion of Mr Listers old mill at Manningham, where they made a considerable amount of money, enjoying uninterrupted good trade. About 1850 Mr Hill retired altogether from participation in the business, which was then carried on solely by Mr Drummond himself. He still continued to occupy Listers Mills, but a few years later, Mr Lister wanted an increase of rent and this led Mr Drummond to the conclusion that he had better look out for a home and habitation for the growing requirements of his trade. Looking round for a suitable site he at length fixed on a field in Lumb Lane, a place which then bore no resemblance to its appearance today, as suited for his requirements. Land it may be taken for granted was not at the price it is now, and Lumb Lane was more composed of fields than dwelling houses. The site covered an area of ten acres and was purchased from Mr Francis Sharpe Powell. It has proved admirably adapted for such a purpose and Mr Drummond at once instructed Messrs Lockwood and Mawson ( now Messrs W and R Mawson) the well known architects of the townm to prepare sketch plans. This would be 1856, and the idea of the senior partner in the firm was not only to construct a mill or mills, but lay out sufficient ground on the higher slopes to build cottages for his workpeople and others. The first plans for the mills contained what is now known as the old mill, and warehouse and a small weaving shed, together with the requisite boiler and engine house and the chimney shaft, which is a conspicuous figure in the district. It may be mentioned that there was good deal of fine clay in the sub soil of the district, and in making the excavations Mr Drummond determined to utilise this in building the inner walls so as to make the buildings fireproof. With this view in end he built a small chimney shaft and brick ovens at the top of the mill site and the whole of the bricks used in the building were constructed on the site. The warehouse fronts to Lumb Lane, to which it has a frontage of 284 feet. It is 35 feet wide and a turn at the top end nearest Belgrave Place of about 45feet. It is three storeys high and excellent light is provided for the workers from 96 windows which front to Lumb Lane. A basement runs along the lower end for about one third of the distance of the warehouse and at the same end on the ground floor is the counting house and the private office of the firm. Opposite is the Lodge , and further down the yard is the chimney shaft, boiler house and engine houses . The old mill which stands at right angles to the warehouse , has a height of five storeys, is 175 feet long and 50 feet wide. It is most substantially built and is filled with the best machinery , and since the commencement of operations therein an enormous quantity of weight of yarn has been turned out. Adjoining this is what is known as the old engine house, which contains a fine beam engine which still runs after nearly 30 years of uninterrupted service. It was one of the first constructed by the Bowling Iron Company, and is of 600 indicated horse power. It supplied the motive power to the old mill and weaving shed but now it is only used for the supply of power to the old mill. Directly opposite the engine house is the boiler house, which at first contained four boilers, but since the extensions of the mill and the weaving shed has been enlarged to accommodate six double box boilers. In connection with these it may be mentioned that there is attached an economiser, which is one of the largest in the town. It contains 520 pipes which aid in supplying hot water to the boilers and we understand that the only other of equal size is one in use at the mills of Mr S.C.Lister at Manningham Mills. Dealing with the features of the works in point of construction mention may here be made of the ornamental chimney stack, a good view of which is given in our illustration. At the period of its erection it was one of the highest in the town and several hundred tons of bricks and stones were used in its construction . It is what is known as an octagonal chimney and rises to a height of 180 feet, which secures an exceptionally good draught for the chimney. The flue is six feet in diameter. The outside at the base shows a diameter of 22 feet, which is gradually lessened until it is about 10 feet just beneath the heavy cornice which crowns the top. It is lined with a heavy fire brick shield to a good height.

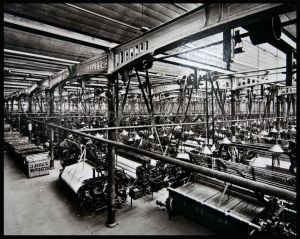

The weaving shed is situate in the centre of the block of buildings, being surrounded on one side by the warehouse, on the other by the old mill and again by the new mill. It is one of the most spacious in the district. From time to time various additions and extensions have been made to it, and its present measurements are 175 feet long by 188 feet wide, the entire floor area being 32,900 square yards. It will be seen at first glance that this afford space for an enormous number of looms, especially of the narrow sort, but the change of times and of machinery has considerably reduced this number. For many years the firm was like the rest of the manufacturers engaged in the production of plain and fancy goods, and was able to produce some specialities which were in good demand now, with the changes of fashion, instead of ladies dress goods the firm is largely employed in the production of gentlemans clothing and the change from narrow to broad looms with the accompanying menders has naturally reduced the number of looms. The firm was one of the earliest to note the change which was overcoming the Bradford trade and to their credit it may be said that they were one of the pioneers of the worsted coating trade in Bradford. In this branch of industry they have been largely engaged for a number of years and at present have over 200 looms engaged in this branch of business alone, whilst in the weaving shed there are altogether about 350 looms running. From this may be easily gathered the immense quantity of wool used in a 12 month.

The steady expansion of the trade of the town that the firm in 1869 to take an extension of their premises, and the work of erecting the new mill was commenced in that year, the building being completed and opened in 1869. It is a fine, lofty and massive building, and the accommodation it provides enabled the firm to overtake the pressure of business. It stands at a right angle to the old mill and it is that which is boldly shown in our illustration. It is 237 feet long with a width of 55 feet and is seven storeys in height with a basement running the entire length. It is fireproof throughout both in the walls and the floors, the latter of which are supported on iron columns with iron beams. It also was erected from the designs of Messrs W & R Lockwood, and like the rest of the works has been constructed in the most substantial manner. The outer walls are of Yorkshire stone, with an inner lining of fireproof bricks. Adjoining the new mill and between that and the old engine house, a new engine house was erected at the same time. In this is placed one of the largest beam engines of the district, made by Messrs John Wood & Co, of Sowerby Bridge. It is of 1200 indicated horse power. There are four cylinders, each of 43 inches diameter and they have a seven feet stroke. The diameter of the fly wheel is 22 feet , the steel fly wheel shaft is 17 inches in diameter.

Bradford grew in size and importance during the Industrial Revolution. Prior to this Bradford’s main claims to being historically significant are based largely around her involvement in the English Civil War, when the siege of Bradford and the circumstances surrounding this event arguably altered the cause of the conflict and thus English history.

The evolution of machinery in the eighteenth and nineteenth centuries saw the town turn into a city as a great deal of wealth was generated by the profitable woolcombing industry. The period saw the city come to the fore of British domestic politics with fine examples of social change occurring around the City. Titus Salt for example, and later on the events that led to the foundation of the Labour party.

In the first half of the nineteenth century Bradford was transformed from a small town to the worsted fabric capital of the world, with a population of over 100,000 and 129 working mills. This new-found wealth led to the construction of some of the city’s most enduring landmarks and civic buildings. Huge mills and larger than life mill owners such as Illingworth, Lister and Foster dominated the scene. The opening of the world’s largest factory in 1853, Titus Salt’s Saltaire Mills, where raw wool went in and finished cloth came out, symbolised the industry’s strength and innovation. The success of the city however was grounded not only in producing cloth but in its marketing and selling via the newly-built Wool Exchange and the warehouse quarter known as ‘Little Germany’.

Conditions in housing and health however, lagged far behind. The average life expectancy was eighteen and half of all children never reached their fifth birthday. Yet people continued to flock to Bradford for work from the surrounding countryside and further away. By 1851 ten per cent of the population was Irish-born, establishing the close link that was always to exist in Bradford between textiles and imported labour.

By the beginning of the twentieth century the number of mills in the Bradford area had grown to 350, but the industry was facing increasing pressure from changes in fashion and foreign competition. The industry moved towards producing specialised products and smaller units. Although both World Wars boosted trade the story of Bradford textiles since 1900 has been one of decline.

The economic slump following the Second World War marked a turning point for the textile industry. Although some mills responded by introducing faster looms from abroad and continental shift systems they were unable to prevent a downturn in the industry. Local people looked to other areas of work with better prospects, pay and working conditions. The textile industry looked abroad to recruit a labour force it could afford: first East European Volunteer Workers, then Italian women and finally Asian men

In the early 1960s some 160,000 were employed in textiles in Britain, 50,000 of them in Bradford. During the 1970s bankruptcies and belated investment in new technology slashed the labour force and created record unemployment. By the 1980s textiles were no longer the main source of employment in Bradford.

Since then most of the city’s last big textile employers have disappeared, with household names such as Salt’s, Lister’s and Whitehead’s closing down. The week before Christmas 2002 production ceased at Drummond’s Lumb Lane Mills, putting another 104 people out of work. The Confederation of British Wool Textiles estimated that there were now fewer than 1,000 people left employed in the Bradford textile industry, with 98% of the jobs having been lost in the past 40 years. Other traditional industries which originally attracted migrant labour to the area, such as engineering, have also suffered huge job losses.

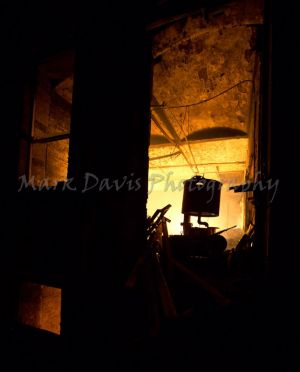

The once thriving Dummond Mill on Lumb Lane Bradford now lies empty.

Like many former former mills the future looks uncertain however plans are in place to make good use of this industrial site..

————————-

January 29, 2016

- Fire at Grade II listed four-storey Drummond Mill in Manningham, Bradford, broke out at around 11am this morning

- Around 100 firefighters using 25 fire appliances say they are still struggling to control the blaze this evening

- They have evacuated residents from around 100 homes located near the mill and warn locals to keep windows shut

- Acting chief fire officer said conditions are ‘extremely difficult’ and added it’s too early to say what caused the fire

Firefighters dealing with an ‘out of control’ fire in a historic mill in Bradford have been forced to evacuate residents from 100 nearby homes.

West Yorkshire Fire and Rescue said the evacuations are a precautionary measure due to high levels of carbon monoxide in the atmosphere.

The fire at the Grade II listed four-storey Drummond Mill in Lumb Lane, Manningham, broke out at around 11am this morning and 100 fire fighters have so far been unable to get it under control.

There are currently 25 fire engines at the incident. A spokesman for West Yorkshire Fire and Rescue said: ‘We advise people to keep windows and doors closed, as there is a great deal of low lying smoke drifting across the area.’

The fire at Lumb Lane Mills, Manningham, broke out at around 11am this morning and fire fighters have so far been unable to get it under control. There are currently 25 fire engines at the incident and the fire service has warned residents in the area to keep their windows shut

Locals have been evacuated from around 100 homes in Lumb Lane, Manningham Lane and Grosvenor Road and have been transported to the Richard Dunn Sports Centre. The fire service is urging residents in Manningham to keep their doors and windows closed.

The spokesman added: ‘Some local residents in Lumb Lane, Manningham Lane and Grosvenor Road are being evacuated to Richard Dunn Sports Centre, Bradford.’

‘This is a four-storey building used for storage and the fire is in the basement. Four firefighters wearing breathing apparatus are tackling the fire, as well as one hose reel and one large jet.

‘Appliances are from: Bradford, Fairweather Green, Odsal, Shipley, Idle, Cleckheaton, Bingley, Illingworth, Morley, Stanningley and Hunslet.’

West Yorkshire Fire and Rescue said evacuations are a precautionary measure due to high levels of carbon monoxide in the atmosphere

Acting chief fire officer Dave Walton told the BBC conditions are ‘extremely difficult’.

He said: ‘It is tremendously hot in there so crews are working hard to get to the fire. It is very thick smoke and intensely hot and very difficult to get to the fire to get water on to it.

‘Because of how hard the crews are working in the basement, we are having to recycle them very, very quickly. They are working in 20-minute sections with the breathing apparatus and then they need relieving by another crew.’

He said it is too early to say what had caused the fire.

Local resident Nayim Rahman, 20, said: ‘I live on the closest street to the mill so I’ve seen it develop throughout the day.

‘I thought they had it under control at one point but now the sky is just black with smoke and there’s even bits of fabric falling too.

‘We all got out as soon as we saw the street filling up with smoke, I’ve got asthma so I have found it hard breathing with all the fumes.

‘There’s loud banging noises coming from the mill and the fire engines have been backing away from it.

‘It’s really scary the whole street is in lockdown and it’s gridlocked in the area, we’re just trying to get away from it.’